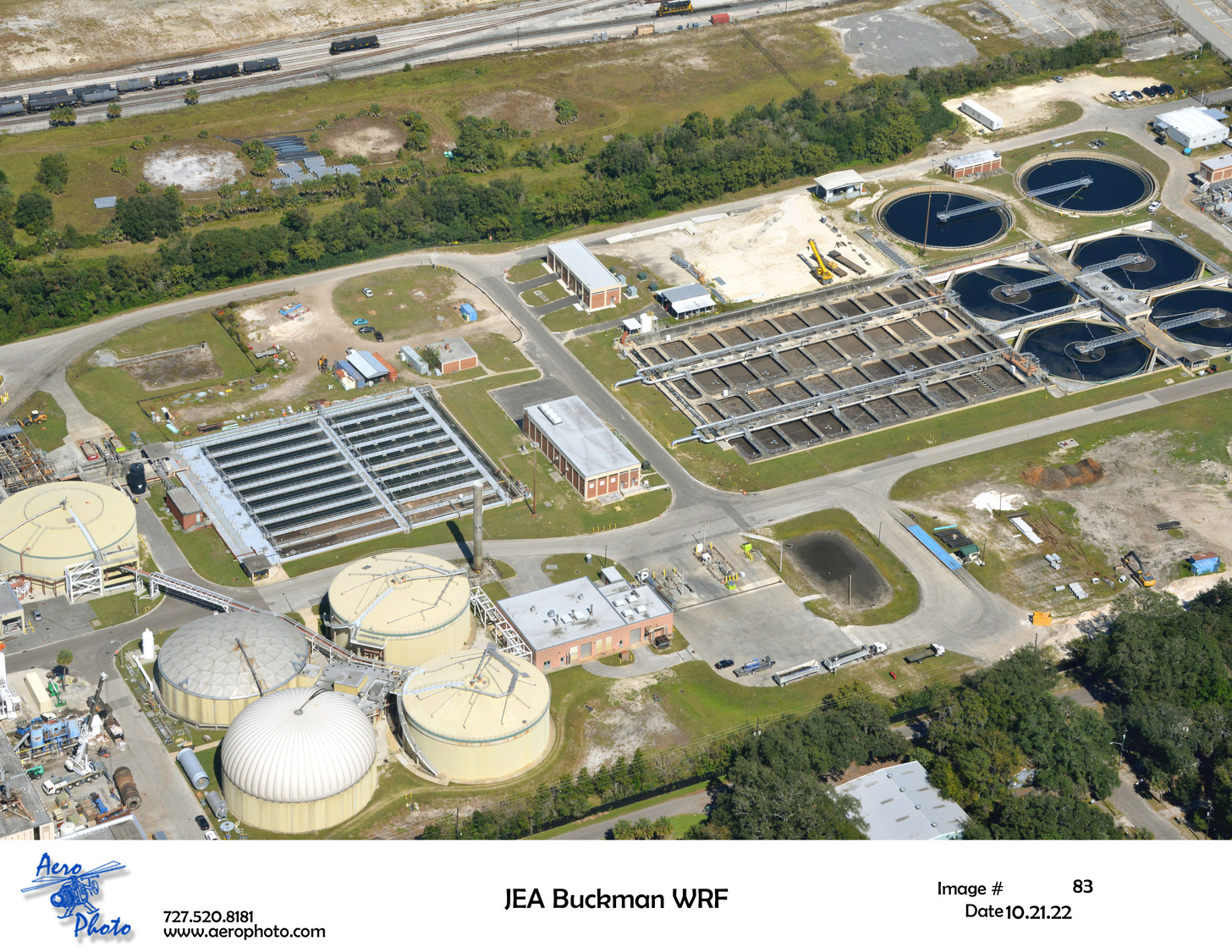

This Construction Management at Risk project at a 52.5 MGD facility includes upgrades and expansions to the majority of the process systems including the fine screens, blower system, aeration basins, secondary clarifiers, UV disinfection, and biosolids processing facility. This project also includes a new biosolids thickening, dewatering, and drying system to produce a biosolids product meeting Class AA requirements for distribution and marketing. The final pelletized product is hauled off-site for residential and agricultural use as a fertilizer. In addition, a new satellite cake receiving station will receive dewatered cake from the satellite water reclamation facilities for processing through the biosolids facility.

The new biosolids facility includes treatment equipment such as gravity belt thickeners, conveyors, centrifuges, and rotary drum dryers. Support processes such as thickening and dewatering Polymer, Muriatic Acid, and Biological Odor Control. The entire plant SCADA system is being overhauled and upgraded along with a new fiber optic communications loop replacing the existing communications system.

The UV disinfection system was a replacement and expansion increasing the capacity of UV treatment to meet the 157.5 MGD peak flow requirements experienced at this facility.

Project Details

LOCATION

Jacksonville, FL

CLIENT

JEA

SIZE

52.5 MGD

CONSTRUCTION COST

$380M